Tungsten Alloy Radiation Shielding

Tungsten Alloy Radiation Shielding

With rapid development of medical science the amount of radiation in our lives is increasing day by day. There is well known X-ray radiation and gamma radiation (energetic electromagnetic radiation), but also radiation of alpha particles (helium atoms), beta particles (electrons), cosmic radiation and others to be considered.

In order to protect patients, personnel and other people from harmful effects of ionizing radiation, such as breast cancer, skin cancer, etc. An excellent radiation-absorbing medium is badly needed.

Why Use Tungsten Alloy Radiation Shielding?

Compared to traditional radiation shielding materials such as lead and boron carbide, tungsten alloys provide excellent density with small capacity. At the same weights high density alloy can provide the same energy absorption as lead using 1/3 less material. When the weight is certain, more density, and the thickness would be thinner. Tungsten alloy material could be made with thinner thickness but high absorption of radiation in high density. That is why tungsten alloy material is suitable for radiation shielding.

During design of shielding, it is calculated according to requirements of shield to abate the multiple shielding materials' thickness.

Formula: K = e0.693 d / △1/2

K: Shield weakened multiple

△ 1/2: The shielding material of the half-value layer values

d: Shielding thickness, with the half-value layer thickness of their units, you need to half-value layer thickness of the quality of translation into the thickness of the material, divided by the density of the material can be obtained.

|

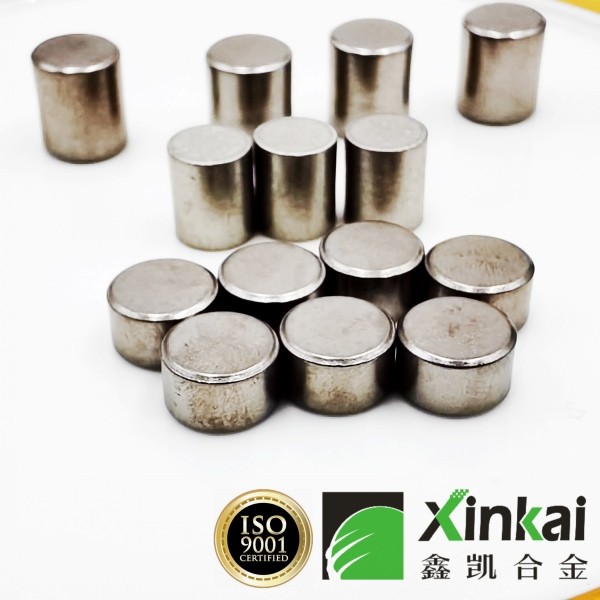

Tungsten Alloy Radiation Shielding |

Tungsten Alloy Radiation Shielding |

Tungsten Alloy Radiation Shielding |

Tungsten alloy radiation shielding include following applications:

Geologging

Geologging is an exploration technique used mainly in the oil and gas industries. It is also known as wire line logging and borehole logging. A gamma ray source is lowered into a borehole and the radiation penetrates the rock strata. This data can then be analyzed to determine whether deposits of gas or oil are present. Tungsten alloy is used to shield the radioactive source and acts as a collimator for the gamma beam.

Pipeline Inspection Gamma

Radiation is used to inspect welds and to detect cracks in pipelines. A gamma source is mounted on a remote-controlled wheeled trolley (sometimes called a "pig") and travels inside the length of the pipe. Tungsten collimator is used to direct the radiation onto the target, whilst the radioactive source is housed inside tungsten shielding.

Industrial Radiography

Industrial radiography uses gamma radiation to detect structural faults in materials such as metal and concrete. As with pipeline inspection, the equipment uses tungsten shielding, coupled with a tungsten collimator.

Thickness, density and level gauging radioactive sources are used in industrial processes to measure thickness, density or levels of materials during production e.g. paper, plastic film, steel sheet or surface coatings. The material passes between a radioactive source, which is housed in tungsten alloy, and a detector. The strength of the detector signal is used to measure the thickness, density or level of the material.

Homeland Security and Border Control

The penetrating power of radiation has also been put to use in the fight against terrorism. The Homeland Security industry has designed scanners that use gamma radiation to detect objects in cargo containers or airline baggage.

The radioactive sources are very strong and require tungsten shielding to protect security staff and members of the public from the radiation. A tungsten collimator is also required to direct the gamma radiation onto its target.

Tungsten alloy is a suitable material for radiation shielding. If you have any interest in tungsten alloy radiation shielding, please feel free to email us: [email protected] or call us: 0086 574-88152763